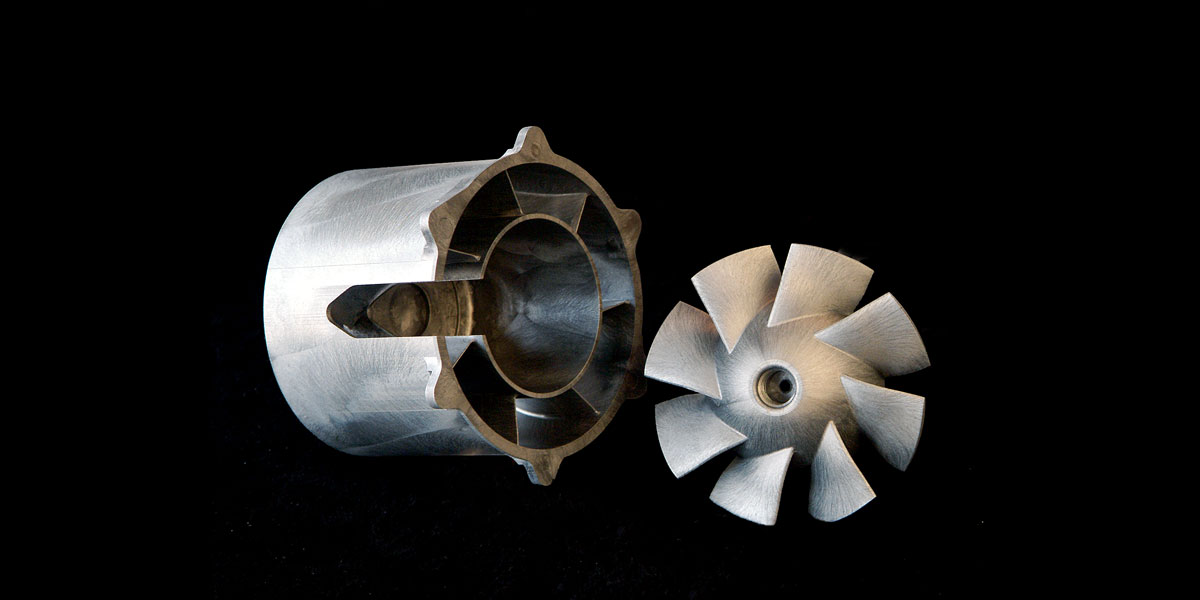

Prototype parts are carefully checked and evaluated for compliance to drawings and all specifications. We then consult with you for your final prototype approval.

Production parts are run in quantity in a white room within our modern molding facility.

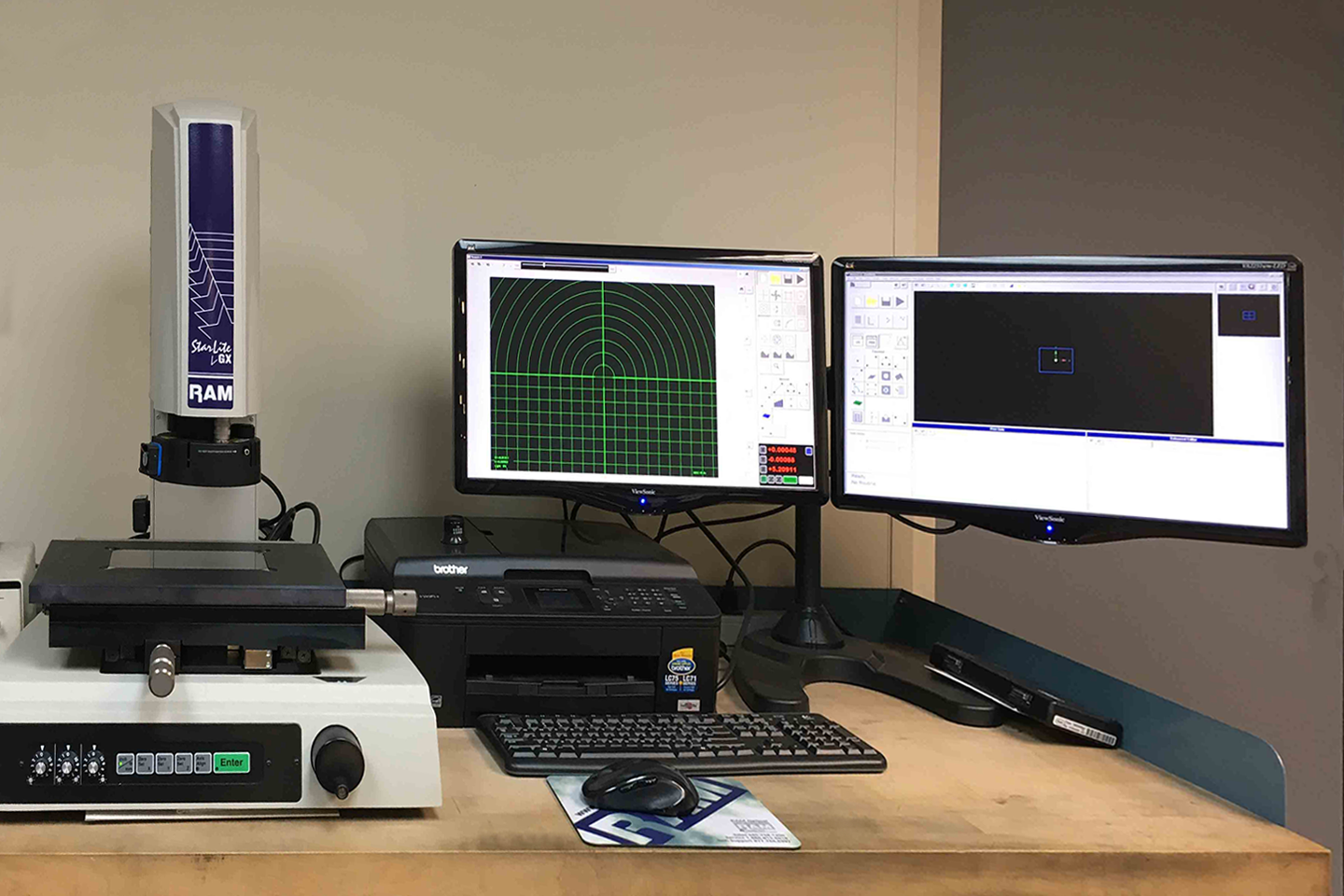

Our stringent quality assurance specialists sample parts and perform a full first-piece inspection utilizing statistical process control procedures and the latest available test equipment. Wycon’s inspection procedures meet industry regulations as well as ISO 9001:2015. Wycon is F.D.A. registered.

A microcomputer-assisted Toolmaker’s Microscope precisely measures dimensions and tolerances to ensure that the finished product meets or exceeds all specifications. Inspection equipment includes: